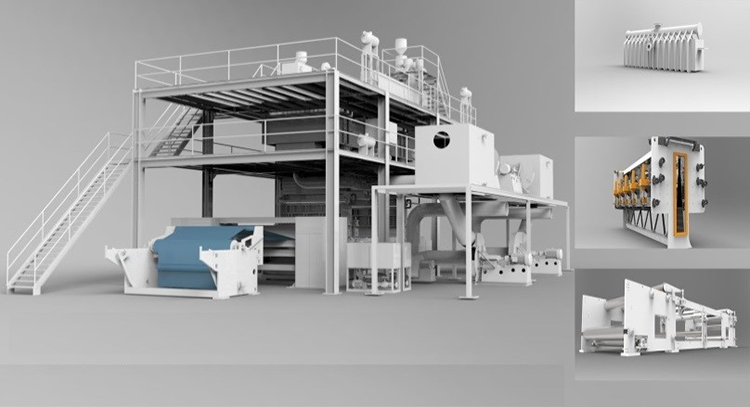

Meltblown, SPUNBOND, SMS, SSMS Beam PP Spunbond Nonwoven Fabric Equipment

Description

The characteristics of the 1600mm SS produced by Supxtech : Use equipment from famous professional manufacture and combined with Supxtech technology ,forming advanced, reliable and stable SS production line .

The 1600mm SS machine key equipment following companies :

Screw extruder (JINHU Or JWELL)

Calender GUANGYU/QIAODE

PLC SIEMENS

Frequency converter ABB

Temperature control Temperature control mould

Melt roots blower GD,USA

Melt spinning beam China

Melt spinning box China

Spinnerets HUIWU,CHANGZHOU

Low voltage components CHNT

Function

A:health usage:operation suit ,garment ,face mask ,diaper,sanitary napkin,disposable hygiene product ,ect:

B:Home decoration :shipping bag,wall covering fabric ,table cloth ,bed sheet,bedspread,etc;

C:Lining for clothes or shoes :lining ,adhesive interlining ,shoe lining ,ect:

D:Agricultural usage:protection cover ,nursery cover,etc.

Technical Process

Spunbond Nonwoven Fabric Production Equipment:

Raw material with Suction feeder device---->Screw extruder---->filter---->Metering

pump---->Suction device--->Spinning box ( Spinneret ) ---->Cooling system

---->Stretching device(2Sets)

---->Web forming machine---->Calender---->online winding machine&Slitter

1. PP chips requirements

PP color master batch and additive

2. Products Width:1600mm

3.Spun bond Filament denier:1.8-2.3denier

4.Output:Based 40 gsm, max 3000tons/year,300days running ,24hours running ;Based 15 gsm, max 2800tons/year,300days running ,24hours running ;

5.Weight range:13-200g/m2

6.Maximum diameter of fabric per roll:1200mm

7.Design speed:≦350m/min Running speed:≦300m/min

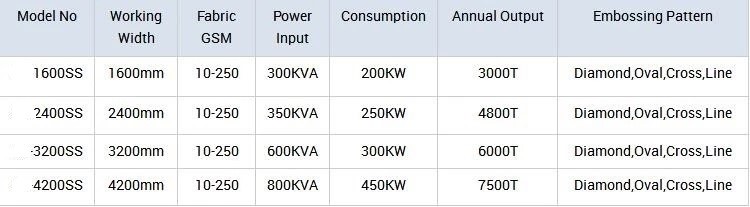

SS Machine Details

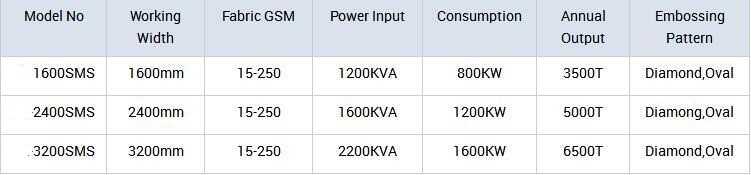

SMS Machine Details