Original Factory Lightweight Work Coveralls - PVC Plastic Extrusion Foam Sheet Board Line – SuperX

Original Factory Lightweight Work Coveralls - PVC Plastic Extrusion Foam Sheet Board Line – SuperX Detail:

Description

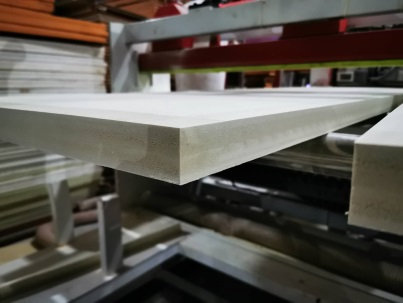

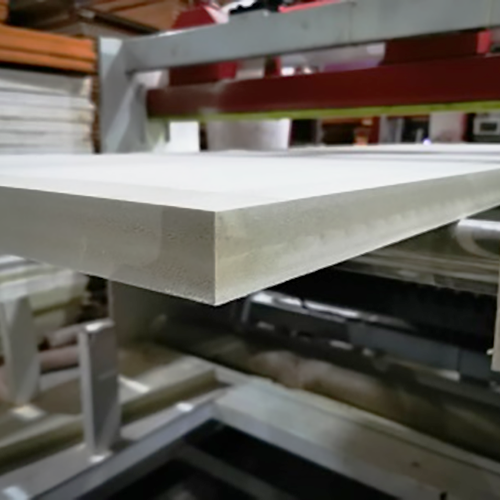

1.PVC foamed board line is used to produce crust pvc foam board which are used in furniture, cabinet,decoration, advertising etc.

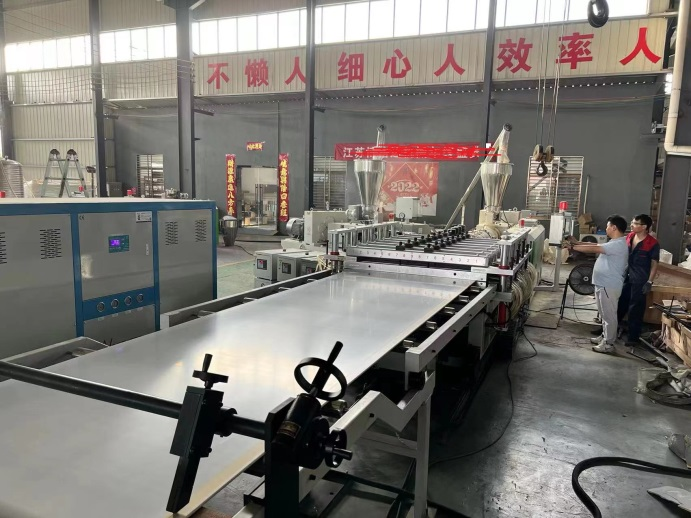

2.PVC Foam Board Machine is our latest updated products. It’s continuously improved on the basis of requirements and feedbacks from our customers and combined with foreign advanced technology. It shows superior performance, high reliability and practicality with its compact structure, advanced configuration and outstanding output in the production of 3-20mm thick, high-qualified PVC foam board.

3.All the electrical components are top quality, like SIEMENS, ABB, OMRON, SCHNEIDER, etc.

4.Wood-plastic products is as a substitute for traditional wood products, greatly reduce the demand for wood. According to the demand, Acemech specially designed the calibration forming technology for PVC wood plastic foam, low foam / no foam and cold push solution for PE/PP wood plastic.

Technical Data

| Model | Extruder | Width | Thickness | Capcity |

| 900mm | SISZ80/156 | 915mm | <25mm | 350kg |

| 1220mm | SISZ80/156 | 1220mm | <25mm | 350kg |

| 1560mm | SJSZ92/188 | 1560mm | <25mm | 500-600kg |

| 1830mm | SJSZ92/188 | 1830mm | <25mm | 500-600kg |

Usage Of Most Popular Pvc Crust Foam Board Making Machine

Used to make construction panel,decoration panel,balustrade,pavement,steps,outdoor tables,wall panel and chairs,pergola,tree bed,etc.

Material:30-60%straw,wood flour,rice chaff mixed with recycled pvc pp pe powder.

Undecomposable,deformation free,fade resistant,insect damage resistant,good fireproof performance,crack resistant,and maintenance free etc.

Competitive Advantage

The Line has the feature of low waster of energy, good performance, high speed and high efficiency, atc. The finished profiles produced by this machine has the feature of good surface, stronger compression resistance, light and heat stability, low size-changing and ageing resistance.

Machine Display

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for Original Factory Lightweight Work Coveralls - PVC Plastic Extrusion Foam Sheet Board Line – SuperX , The product will supply to all over the world, such as: Monaco, Kenya, Liberia, By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.