Manufactur standard Carbon Fiber Thermoplastic Composite - Continous Fiber Reinforced Thermoplastic Composite Tape Production Line – SuperX

Manufactur standard Carbon Fiber Thermoplastic Composite - Continous Fiber Reinforced Thermoplastic Composite Tape Production Line – SuperX Detail:

PP/PE/PA/PET continuous glass fiber reinforced thermoplastic tape production line

Lightweight products are in growing demand. Supxtech thermoplastic composites offer a lightweight material solution without compromising on performance and design. They can be used to manufacture components that are not only extremely light, strong and durable, but also offer new creative freedom for product designers.

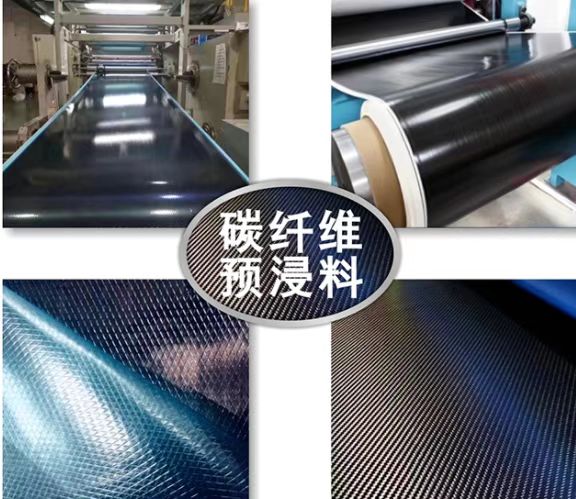

Continuous fiber reinforced thermoplastic(CFRTP) tapes are based on continuous fiber and thermoplastic resin as reinforced material and matrix respectively. It can manufacture high-strength, high-rigidity, high-toughness composite material through special processes. As the high strength of continuous fiber, CFRTP material has excellent mechanical properties, which is widely used in various fields such as aerospace, train, automobile, shipbuilding, container, architectural ornament, pipeline, safety, Sports & Leisure, war industry etc. and more new products have been developed.

It can be coating with PP/PE/PA6 with Glass fiber , the PPS/PEEK/PA6 with cabon fiber. We also can offer the winder machine and slitting machine .

Product Features

Thermoplastic material and various choice

Indefinite shelf life

Environmentally friendly ,Recyclable

Light weight, high strength, excellent mechanical properties

Flexible product design, controllable material properties

Excellent anti corrosion and moisture resistance

Advanced technology, automatic production

Width :600mm 800mm 1000mm 1200mm

Nylon (PA) + continuous carbon fiber reinforced thermoplastic

Lightweight products are in growing demand. Supxtech thermoplastic composites offer a lightweight material solution without compromising on performance and design. They can be used to manufacture components that are not only extremely light, strong and durable, but also offer new creative freedom for product designers.

Nylon (PA) + continuous carbon fiber reinforced thermoplastic unidirectional prepreg belt was produced by thermoplastic extrusion melt impregnation method.

1. Type of fiber used: carbon fiber or glass fiber;

2. Use extruder model: single screw extruder or twin screw extruder;

3. PA: carbon fiber = 50% : 50%;

4. Can use plastic raw materials: PA/PP/PE;

5. Product thickness: 0.2-0.25mm;

6. Production width: 360mm / 635mm;

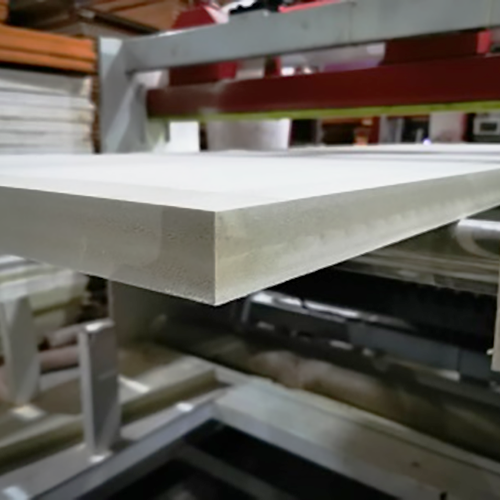

Continuous carbon fiber reinforced PA unidirectional prepreg strips are not sticky on the surface, so they must be laminated using a double strip composite press (belt or steel strip depending on the material). First, the PA unidirectional prepreg strip is placed manually and then laminated according to the desired thickness to form the PA unidirectional prepreg strip laminate. The laminating temperature is between 230℃***270℃.

The advantages and disadvantages of continuous carbon fiber reinforced PA prepreg will directly affect the performance of unidirectional prepreg zone laminates. Continuous carbon fiber reinforced PA prepreg has high tensile strength to ensure the strength properties of unidirectional prepreg zone laminates.

PPS continuous carbon fiber reinforced thermoplastic tape production line

Lightweight products are in growing demand. Supxtech thermoplastic composites offer a lightweight material solution without compromising on performance and design. They can be used to manufacture components that are not only extremely light, strong and durable, but also offer new creative freedom for product designers.

As a kind of high performance engineering material, polyphenylene sulfide (PPS) has many advantages in performance. However, due to technical reasons, the high-end continuous carbon fiber reinforced PPS-UD belt had to be imported. After years of painstaking research and development, we has mastered the core technology of PPS+ continuous carbon fiber thermoplastic impregnation process, and launched (CF/PPS) thermoplastic UD belt production line to the market.

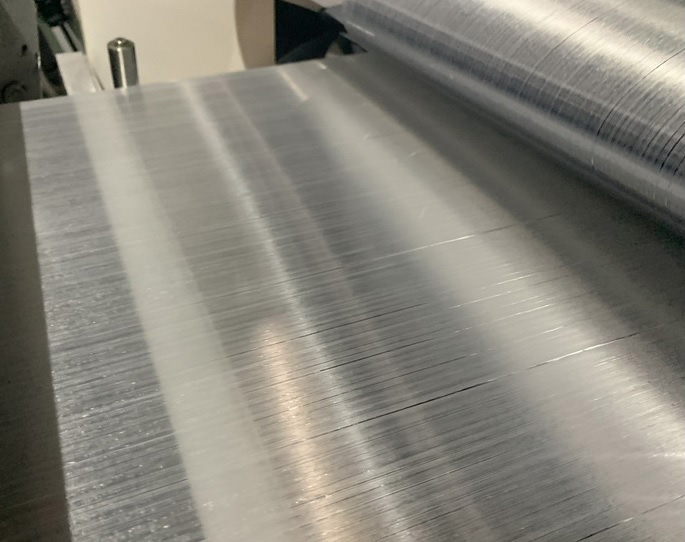

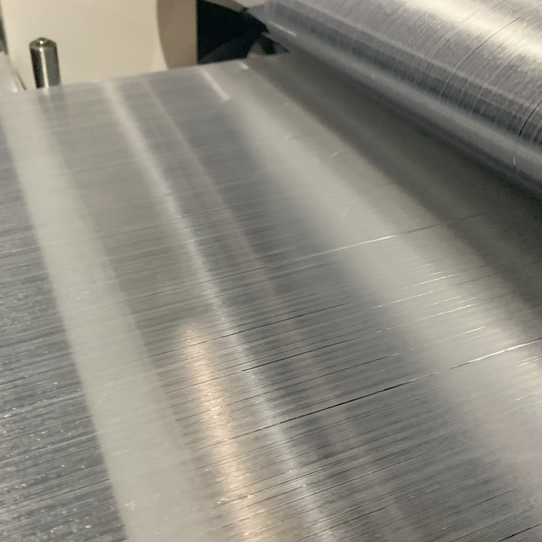

The model introduced by us adopts the melt impregnation process, which is different from the conventional powder method and solution method, which can realize the continuous and stable forming production of PPS-UD tape, and has the conditions of quantitative production. PPS high performance particles were fused and plasticized by a special high temperature extruder, and the melt volume was quantitatively transported, and the PPS particles were dispersed impregnated with continuous carbon fiber in the core impregnation mold.

The width of the product is 300-600mm,

The thickness is 0.2-0.22mm.

The specific gravity of CF and PPS is about 1:1.

The produced UD TAPE has smooth surface, good impregnation effect and uniform distribution of continuous fibers. Can meet the aerospace, weapons, military, rail transit, medical sports and other professional application fields.

Peek continuous carbon fiber reinforced thermoplastic tape production line

Lightweight products are in growing demand. Supxtech thermoplastic composites offer a lightweight material solution without compromising on performance and design. They can be used to manufacture components that are not only extremely light, strong and durable, but also offer new creative freedom for product designers.

(CFRTP-UD belt) production line features:

1. Process temperature: 400°C;

2. Production of fiber type: carbon fiber;

3. PEEK polyether ether ketone: carbon fiber = 50% : 50%;

4. Can produce plastic raw materials: PEEK;

5. Production speed: 2-4 m/min;

6. Production product thickness: 0.2-0.25mm,

7. Production width: 600 mm

Advantages of continuous carbon fiber CF/PEEK composites:

1. Good fracture elongation and fracture toughness

PEEK, as a representative of high performance thermoplastic polymer, has a fracture toughness of 2.0 KJ/m, 20 times that of epoxy resin.

2. Excellent anti-delamination ability and fatigue resistance

PEEK has good impact resistance, it is a heat resistant resin with good impact resistance. At the same time, PEEK has high rigidity, good dimensional stability, small linear expansion coefficient, and excellent long-term creep and fatigue resistance.

3. Excellent resistance to chemical corrosion

PEEK HAS excellent chemical corrosion resistance to acid, alkali and almost all organic solvents. It is only corroded by halogen and strong acid at high temperature, and only dissolved in concentrated sulfuric acid at room temperature.

4. Excellent moisture and heat resistance

PEEK has low moisture absorption rate, good moisture and heat resistance, can still maintain good mechanical properties under high temperature and humidity, in addition to outstanding hydrolytic resistance, low moisture absorption and permeability, steam, water and seawater resistance.

5. excellent sliding wear and fretting wear

PEEK can maintain high wear resistance and low friction coefficient at 250 ℃.

6. Biocompatibility

Studies have shown that short carbon fiber reinforced PEEK implanted into animals has low cytotoxicity, meets the cytotoxicity index of medical implant materials, and has good blood compatibility and histocompatibility.

7. X-ray

PEEK has good transmission performance, does not produce artifacts such as metal implants in X-ray, CT examination, convenient for patients in medical examination and so on.

PP/PE continuous Aramid fiber reinforced thermoplastic tape production line

Lightweight products are in growing demand. Supxtech thermoplastic composites offer a lightweight material solution without compromising on performance and design. They can be used to manufacture components that are not only extremely light, strong and durable, but also offer new creative freedom for product designers.

Aramid fiber prepreg belt is a new type of high-tech synthetic fiber, with ultra-high strength, high modulus, high temperature resistance, acid and alkali resistance, light weight and other excellent properties, has been widely used as a high-tech fiber material in aerospace, mechanical and electrical, construction, automotive, sporting goods and other aspects of the national economy. In aviation and aerospace, aramid fiber saves a lot of power fuel because of its light weight and high strength. The arylon fiber unidirectional prePREg tape production line developed by Jinwei Machinery is mainly used for arylon fiber reinforced thermoplastic composite pipe. Aramid fiber reinforced thermoplastic composite tube is a kind of high pressure plastic composite pipe, with good flexibility, corrosion resistance, high pressure resistance, impact resistance, wear resistance, light weight, easy to connect, coiling, quickly laid over long distances without joint etc., is a good way to overcome problems of steel pipe corrosion and pressure problem of plastic pipe, can be used in the oil and gas drilling, High pressure long distance transportation of natural gas and a variety of pipelines requiring higher pressure delivery medium distance .

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Manufactur standard Carbon Fiber Thermoplastic Composite - Continous Fiber Reinforced Thermoplastic Composite Tape Production Line – SuperX , The product will supply to all over the world, such as: Madrid, Dominica, Latvia, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!