High Quality for Plastic Extrusion Profiles - One step Breathable film line – SuperX

High Quality for Plastic Extrusion Profiles - One step Breathable film line – SuperX Detail:

Product Description

Waterproof and breathable film is also called a new type of polymer waterproof material, because of its microporous, hydrophobic, oily and breathable waterproof and oil-proof function, has been widely used in medical, precision electronics, LED outdoor lighting, automotive lights, communications, chemical, security and other industries.

The technical requirements of waterproof breathable film are much higher than the general waterproof material; From the quality point of view, waterproof breathable film has other waterproof materials do not have the functional characteristics.

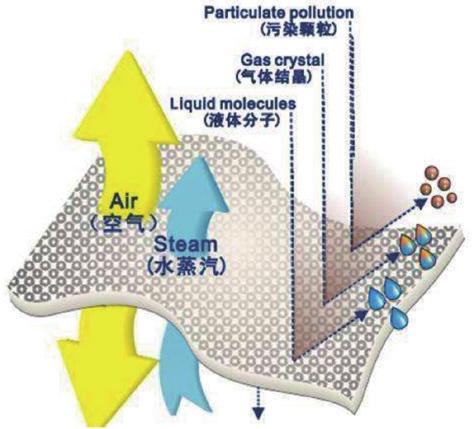

How the permeable film works

In the state of water vapor, water particles are very small, according to the principle of capillary motion, can smoothly penetrate into the capillary to the other side, so as to occur vapor penetration phenomenon. When water vapor condenses into water droplets, the particles become larger, due to the effect of water surface tension (water molecules between each other “pull and fight”), water molecules can not smoothly out of the water into the other side, that is to prevent the penetration of water, so that the vapor permeable film has a waterproof function.

The material of the breathable film

Waterproof breathable film technology was first introduced from European and American countries, but the production process of domestic products is various, the product quality of each manufacturer is uneven, failed to form a unified quality standard. In fact, waterproof breathable film is mainly composed of three layers: PP spunbonded non-woven, PE polymer breathable film, PP spunbonded non-woven. The function of spunbonded non-woven fabric is mainly to enhance tension and hydrostatic pressure and protect the middle layer (breathable film), the real breathable is mainly by the middle layer of PE polymer breathable film.

Production process of breathable film

At present, the domestic market mixed, the production of real waterproof breathable film manufacturers are very few, many factories or sellers are promoting their own waterproof breathable film is good, almost most users have not thought of, some manufacturers provide waterproof breathable film is not waterproof.

In fact, the real waterproof breathable film should be high permeability, high temperature resistance, anti-aging, hydrostatic pressure of more than 2 meters. The production process should be pure thermal composite technology, without glue, so it can reach temperature resistance of more than 110 degrees, high strength and anti-aging. This is the product that can truly meet the European Union standard at present in China, and it is the latest domestic technology

Product detail pictures:

Related Product Guide:

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for High Quality for Plastic Extrusion Profiles - One step Breathable film line – SuperX , The product will supply to all over the world, such as: Azerbaijan, Thailand, Slovenia, When you are keen on any of our items following you view our product list, please feel free to make contact with us for inquiries. You'll be able to send us emails and get in touch with us for consultation and we shall respond to you as soon as we are able to. If it's convenient, you could find out our address in our web site and come to our enterprise. or additional information of our items by yourself. We're generally ready to build lengthy and steady co-operation relations with any possible shoppers within the associated fields.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!