High definition Composite Curing Oven - Fiber Glass Chopped Belt Presser Machine – SuperX

High definition Composite Curing Oven - Fiber Glass Chopped Belt Presser Machine – SuperX Detail:

Description

Therefore, it is an ideal substrate for roofing linoleum and other materials and a surface reinforcement material for automotive GMT board. At the same time composite molding requirements.

Product features

• Uniform fiber distribution

• High tensile strength

• Good tear resistance

• Suitable for all kinds of adhesives

Fiberglass cut felt is an important non-woven reinforcing material for FRP hand pasting process. It is a continuous fiberglass filament or fiberglass filament or no twist roving short cut without directional uniform distribution, by powder binder.

Short-cut felt products can be widely used in chemical industry: anticorrosive pipes, ships, auto parts, sanitary ware, building components, entertainment and living and other FRP products, with excellent mechanical strength and product application performance.

This product line adopts fiberglass filament or non-twist roving short cut felt, with good uniformity, high degree of self-control, low energy consumption, convenient operation and maintenance.

This product line can produce powder, emulsion, no alkali, medium alkali cut felt.

Fiberglass chopped filament mat or simply cut mat is a major non-woven addition to fiberglass. FRP hand paste process, a large amount of increased material, also used in some mechanical molding process, such as RTM, winding, molding, etc. The non-directional distribution of the filaments made up for the deficiency of the checkerboard and improved the interlayer shear strength of FRP products significantly. It is a powder or emulsion binding agent, so fast penetration, good permeability.

Short cut felt products are widely used in chemical anti-corrosion pipeline, refrigerated car box, car roof, high voltage insulation materials, reinforced plastics and boats, sanitary fixtures, chairs, flower plates, building components, entertainment equipment, statues and other FRP products. Products with high strength and smooth appearance.

performance

1. No directional distribution, uniform distribution, with excellent mechanical properties.

2. Good coating performance, suitable for mold cavity of complex shape products.

3. Strong ability with resin, smooth appearance of products.

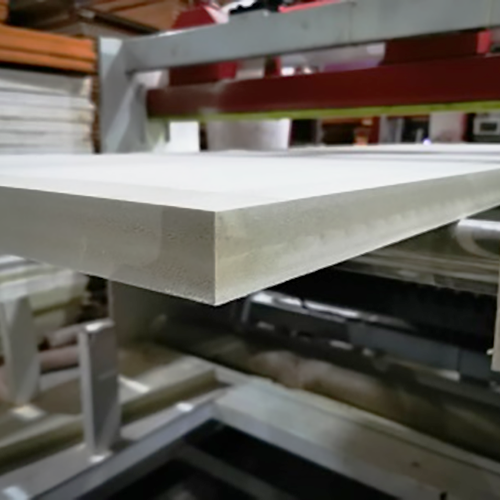

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for High definition Composite Curing Oven - Fiber Glass Chopped Belt Presser Machine – SuperX , The product will supply to all over the world, such as: Juventus, Latvia, Swedish, We supply professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia. Adhering to the business philosophy of ‘customer first, forge ahead', we sincerely welcome clients from at home and abroad to cooperate with us.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!