Aerogel Thermal insulator coating products

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for Aerogel Thermal insulator coating products, Since establishment in the early 1990s, we have set up our sale network in USA, Germany, Asia, and several Middle Eastern countries. We aim to be a top class supplier for worldwide OEM and aftermarket!

We retain bettering and perfecting our merchandise and service. At the same time, we do the job actively to do research and improvement for coating fibic sio2, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

Prformance Characteristics

1. Adiabatic high temperature resistance

Low thermal conductivity, conventional product thermal conductivity 0.018~0.020 W/(m•K), the lowest to 0.014 W/(m•K), the temperature section is lower than peer products, the highest can withstand 1100℃ high temperature, heat preservation and insulation effect is 3-5 times of traditional materials, high efficiency and energy saving.

2. Waterproof and breathable

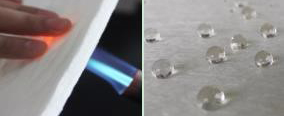

With excellent overall waterproof performance, hydrophobic rate ≥99%, isolation of liquid water, and allow water vapor through.

3. Fire and non-flammable

It has achieved the highest grade A1 in the building combustion grade standard and the highest grade A non-combustible in the automotive interior material combustion grade.

4. Safety and environmental protection

Products have passed RoHS, REACH detection, does not contain harmful substances to human body, soluble chloride content is very small.

5. Tensile and compressive resistance, convenient construction and transportation

Good flexibility and tensile/compressive strength, long-term use of no settlement, no deformation; Light and convenient, easy to cut, high construction efficiency, suitable for various complex shape requirements, low transportation cost.

Application

In industrial field

The electric energy storage, petrochemical industry, industrial kilns and other industries which require piping insulation or furnace insulation parts are need to use high efficiency heat preservation material, aerogel insulation material can effectively reduce heat loss and save heat energy, improve the utilization efficiency of heat source, heat insulation effect is the traditional material 3 ~ 5 times, and longer life.

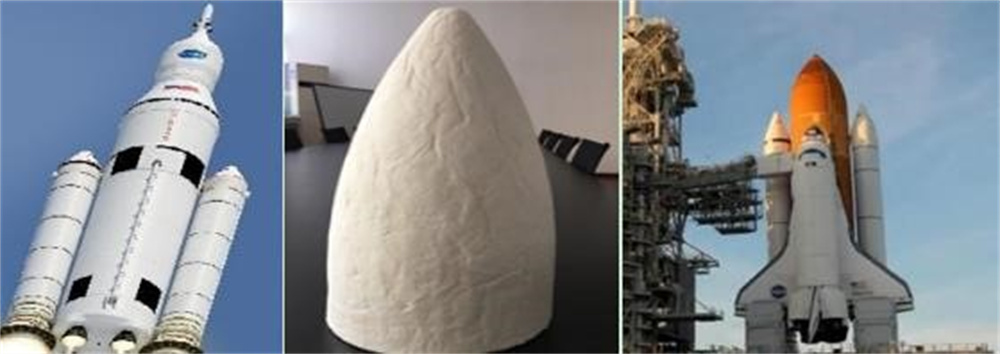

In the aerospace field

Aerogel thermal insulation material can be used as the thermal insulation material of aircraft cabin, which can enhance the thermal insulation effect, reduce the cabin temperature, effectively reduce the amount of thermal insulation material, increase the use space in the cabin, and effectively improve various working environments. Aerogel thermal insulation material can achieve better thermal insulation effect with lighter mass and smaller volume, which has great advantages in the field of aviation and aerospace applications.

In the field of construction

With the continuous improvement of national requirements for energy conservation and emission reduction, and people’s pursuit of quality of life, building insulation has gradually become a key topic in the field of construction. For a building, almost all parts, are involved in the need for thermal insulation, especially in the building wall insulation, roof floor insulation. Silica aerogel can withstand high temperature, generally at 800℃, its structure, performance has no obvious change, is a safe, energy saving, environmental protection of super insulation material.

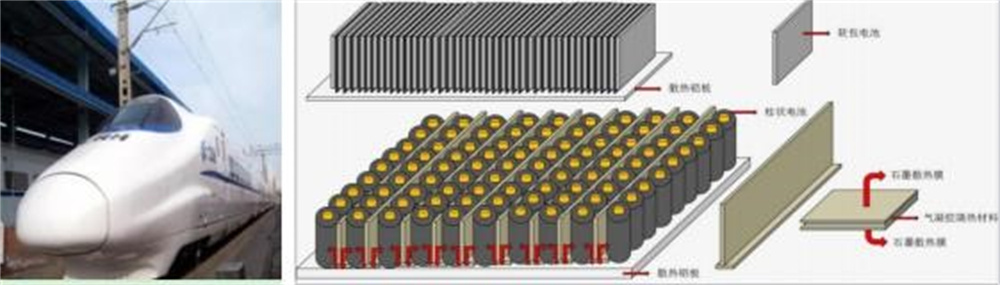

In the field of transportation

The heat insulation performance of vehicle roof is one of the main factors affecting the heat transfer of vehicle body. It is of great significance for analyzing the energy consumption of vehicle operation, determining its air conditioning load, avoiding the occurrence of bad working conditions, and maintaining the comfortable thermal environment inside the vehicle. In the field of new energy vehicles, electric vehicle fire and explosion accidents caused by lithium ion battery “thermal runaway” have been reported frequently. How to effectively ensure the heat dissipation and safety of lithium battery has become the “sword of Damocles” hanging over the head of automobile factories and power battery enterprises. Nanoporous aerogel composite insulation materials have been applied to high-speed trains, the domestic C919 passenger plane, and new energy vehicles, mainly focusing on the heat insulation of transportation vehicles and the protection of lithium batteries in new energy vehicles.

Specification

According to the selection of different substrate, aerogel mat can choose different composite series according to different customer needs and scenarios. At present, there are mainly four series of glass fiber composite aerogels (HHA-GZ), preoxygenated wire fiber composite aerogels (HHA-YYZ), high silicon oxygen fiber composite aerogels (HHA-HGZ) and ceramic fiber composite aerogels (HHA-TCZ). The specification parameters are as follows:

According to the heat insulation mechanism, fabric heat insulation coating can be divided into three types: barrier type, reflection type and radiation type. we suzhou supxtech company can offer the Aerogel coating technology and the machinery , it can be use for the colth , plastic sheet and felt . it widly use for the keep warm area.

According to the heat insulation mechanism, fabric heat insulation coating can be divided into three types: barrier type, reflection type and radiation type. we suzhou supxtech company can offer the Aerogel coating technology and the machinery , it can be use for the colth , plastic sheet and felt . it widly use for the keep warm area.

Barrier heat insulation coating is a kind of passive cooling coating which realizes heat insulation through the impedance effect of heat transfer. The heat insulation mechanism is relatively simple, and the composition with low thermal conductivity or the air with very low thermal conductivity is introduced into the film to obtain good heat insulation effect. It usually has the characteristics of relatively small bulk density, low thermal conductivity and small dielectric constant.

Reflective heat insulation coating is to isolate the solar energy in the form of reflection. Commonly used reflective materials include ceramic powder, aluminum powder, titanium dioxide and ATO (antimony doped tin dioxide) powder.

Common barrier fabric heat insulation coating agent according to the chemical structure, mainly include polyvinyl chloride (PVC), polyacrylate (PA), polyurethane (PU), silicone, rubber emulsion and polytetrafluoroethylene, among which PA and PU are more used; According to the use of medium, can be divided into solvent and water dispersed type 2.

SiO2 aerogel is an amorphous nanoporous material with controllable structure and continuous three-dimensional network structure. And its density is adjustable between 3 ~ 500mg/cm3, is the world’s lowest density of a solid material, porosity can reach 80% ~ 99.8%, pore size between 1 ~ 100nm, specific surface area can be up to 1000m2/g. Due to its unique nanoporous structure, its thermal conductivity is extremely low, as low as 0.017W/ (m•K) at room temperature and pressure, making it the lowest known solid material with thermal conductivity. Because the structure unit of aerogel skeleton is smaller than the wavelength of visible light, it also has good light transmission performance. At the same time, it is inorganic material, with non-combustible or flame retardant effect, in the field of thermal insulation has a wide range of application prospects.